It’s hard to believe the first month of 2018 is already over, no need to fret just yet, there are still 11 more months left to make a positive impact on your business or team. A common objective for the new year might be to increase operational efficiencies- if so, we can certainly help in that regard with any lubricating procedures. The Oil Injection Pump from Welker makes automatic lubrication a breeze!

This device is most commonly used to systematically deliver automatic lubrication for turbine meter bearings. Major process efficiencies have been experienced while using the OIP by Welker in comparison to past procedures, where the lubrication of bearings was once a tedious task. The oil injection pump is a reliable process, that delivers even product with the flip of a switch.

If you are looking for an automatic lubrication system that will evenly lubricate and perform consistently to increase operational efficiencies, the Oil Injection Pump by Welker is your answer.

Where Can an OIP Be Used?

- Turbine meter bearings

- Bearing systems in any machinery that requires periodic lubrication

- Corrosion inhibitor injection

Why You Need An OIP

With regular use of the Oil Injection Pump, many operational benefits can be experienced such as:

- Maintenance time dramatically reduced

- Bearing life is increased

- Accuracy is preserved

Is the OIP For You?

Positions that typically use this device are technicians, engineers, mechanical contractors, and procurement officers. The industries are broad but include some of the following:

- Textile Industry

- Conveyor belt systems

- Rotary pumps

- Other bearings system applications

- Gas Utility

- Gas Transmission

- Industrial Contractors

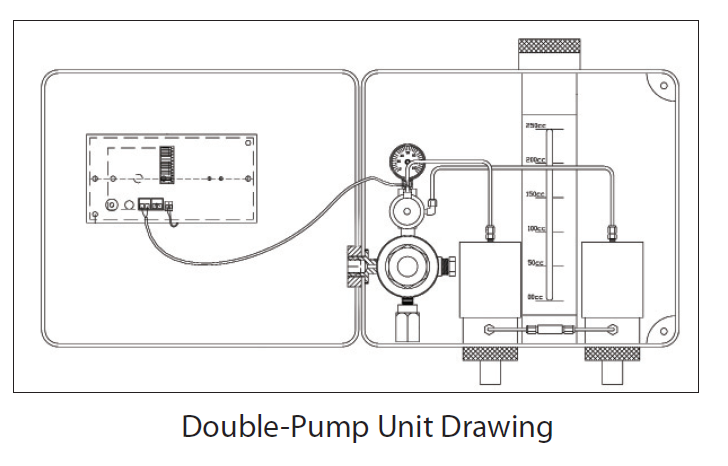

Double Pump option is available- With this setup, you can essentially oil two separate meters from one unit! How’s that for productive?

Features

- Designed for lubrication of meter bearings

- 0.25 cc per stroke

- Fiberglass enclosure or metal if necessary

- 6 VDC, 12 VDC, and 24 VDC

- Low cost

- Reduction of maintenance cost

Benefits

- Compact design that allows for ease of transportation.

- Simple installation and compatibility with virtually any meter make the OIP an excellent choice for automatic lubrication of turbine meter bearings.

- Lubricates evenly and consistently.

- Reduced maintenance time.

- Long product lifecycle with proper maintenance